On August 18, the Central Committee of the Communist Party of China and the State Council issued the "Opinions on Supporting Shenzhen in Building a Socialist Demonstration Zone with Chinese Characteristics." The document proposed strategic positioning for Shenzhen to become a high ground for high-quality development, a model city for rule of law, an exemplar of urban civilization, a benchmark for people's livelihood and happiness, and a pioneer in sustainable development.

The "Opinions" mentioned initiatives such as "taking the lead in building a modern economic system that reflects high-quality development requirements" and "accelerating the implementation of innovation-driven development strategies." These fully demonstrate Shenzhen's promising technological and intelligent future.

As one of Shenzhen's six traditional advantageous industries, the jewelry sector has been focusing on "industrial upgrading under the new economic situation" in recent years. The city has gathered a large number of top-tier jewelry professionals who, through continuous technological innovation and equipment upgrades, have not only brought high-quality, high-profit products to the industry but also injected boundless vitality into Shenzhen's jewelry sector.

However, overall challenges remain unresolved, including product homogenization, a shortage of interdisciplinary talent, overcapacity, intensified market competition, and significant room for improvement in manufacturers' automation and smart manufacturing levels. As the saying goes, "By other's faults, wise men correct their own." In the wave of industrial upgrading, the experiences of some innovative benchmark enterprises may be worth discussing and learning from.

When it comes to Gemhorn Jewelry, many industry insiders are familiar with its story. Over 17 years, the company has grown into a large jewelry manufacturer with four factories, all thanks to its commitment to "innovative smart manufacturing."

When Gemhorn was founded, China's precious metals and products market had just opened, ushering in a new era for the jewelry industry. In 2003, Gemhorn's Plain Gold Factory pioneered palladium jewelry globally, sparking a nationwide palladium consumption frenzy upon its launch, with palladium temporarily replacing gold as the "new darling" of the jewelry market.

During palladium's heyday, Gemhorn foresaw that K-gold's high ductility and colorful features would dominate future markets. Thus, in 2005, Gemhorn established its K-Gold Factory, investing heavily in world-class machine-woven chain production lines.

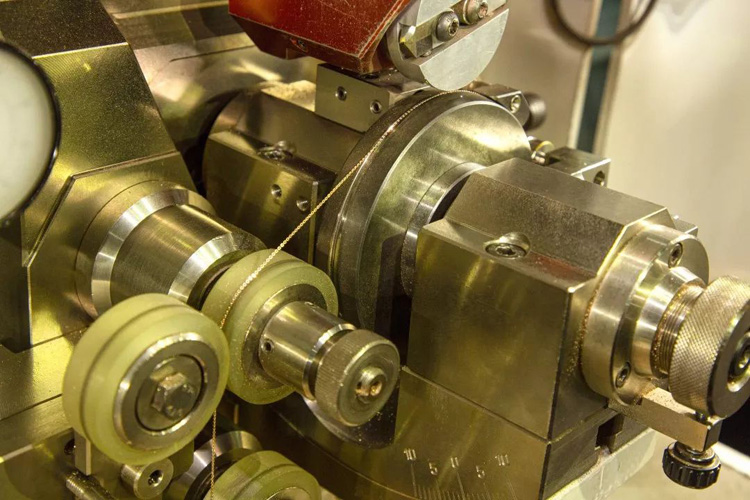

Over the years, the K-Gold Factory has continuously innovated in material development, process improvements, and automation upgrades, achieving multiple technological breakthroughs and earning national invention and utility model patents. With mastery over 400+ machine-woven chain production techniques, the factory boasts minimal material loss and high automation levels, now standing as China's largest and most professional machine-woven chain production hub.

Gemhorn K-Gold Factory's high-end machine-woven chain equipment

Efficiency, precision, and stability are the advantages of automated engraving machines over manual engraving. The skilled application and independent modification of imported machine-woven chain equipment have truly achieved human-machine integration, giving machines a "second life."

In 2011, the Gem Setting Factory was established. As China's first colored gemstone factory to adopt 3D printing and CNC multi-facet processing technologies, it leverages sales big data to analyze end markets. From initially focusing on large-carat colored gemstones to recent affordable luxury and minimalist designs, Gemhorn's colored gemstones precisely align with retail market demands, with one-to-one customization services meeting diverse client needs.

Magpie Joy 18K Ruby Set

Floral Splendor 18K Chrome Tourmaline Bracelet

In 2018, Gemhorn Jewelry's third K-gold production facility—Gemhorn Factory 5—was born. With internationally leading imported K-gold production lines and an exceptional R&D team, Gemhorn developed multiple smart CNC engraving series like "Crystal" and "Linglong" within months. This technology creates unique crystal-like luster on K-gold surfaces, winning consumer favor and leading to sold-out products with overwhelming orders.

Linglong Series

Gemhorn's growth stems from era-driven opportunities but, more importantly, from management's long-term commitment to innovation. Years ago, Gemhorn identified innovation as its core competitive edge, establishing a Technology Development Center dedicated to R&D in automated production equipment, new materials, designs, and processes.

From traditional soldering to imported laser spot welding, Gemhorn's new-generation artisans excel at discovery and innovation, with each technological advancement quietly shaping the industry's future.

Today, Gemhorn leads the industry in smart manufacturing areas like 3D printing, high-speed chain weaving, laser processing, automated engraving, and CNC technology, earning multiple national invention and utility model patents. Known for its extensive new designs, stylish aesthetics, superior quality, and fast delivery, Gemhorn has built an impeccable reputation in the industry.

Red Plum in Snow Solid Gold Jade Pendant

Innovation and transformation are not just trends but essential skills for enterprises navigating changing times. We believe Shenzhen's jewelry professionals will embrace open-mindedness to experience the charm of "innovation-driven change," share the benefits of industrial innovation, and collectively drive sustainable and healthy industry development!

More

Good News to Kick Off the Year | GEMHORN Jewelry Successfully Renews National High-Tech Enterprise Certification!

2026.02.25

One Heart, New Journey | Gemon Group’s 2026 New Year Gala Concludes Successfully!

2026.02.03

GEMHORN Fire Drill Strengthens Safety Defenses, Enhances Full Staff Emergency Response Capability Through Realistic Training

2025.12.04